Agronomics benefits

In-house raw materials

Throughout this model of circular economy, Fertival uses organic matter from pigs that comes from Cooperl’s members farms which provides several advantages to Fertival’s fertilizer products:

- Balanced components of cellulose, hemicellulose and lignin, promoting the ability to generate humus in a sustainable way

- Consistency of the organic matter from our cooperative’s member farmers

- A slow and steady Nitrogen mineralisation leading to optimal crop nutrition and a reduction in the number of fertilizer doses

- A slow and steady Carbon mineralisation leading to humus creation in the soil

- An optimal C/N ratio (Carbon/Nitrogen) enabling good product reaction

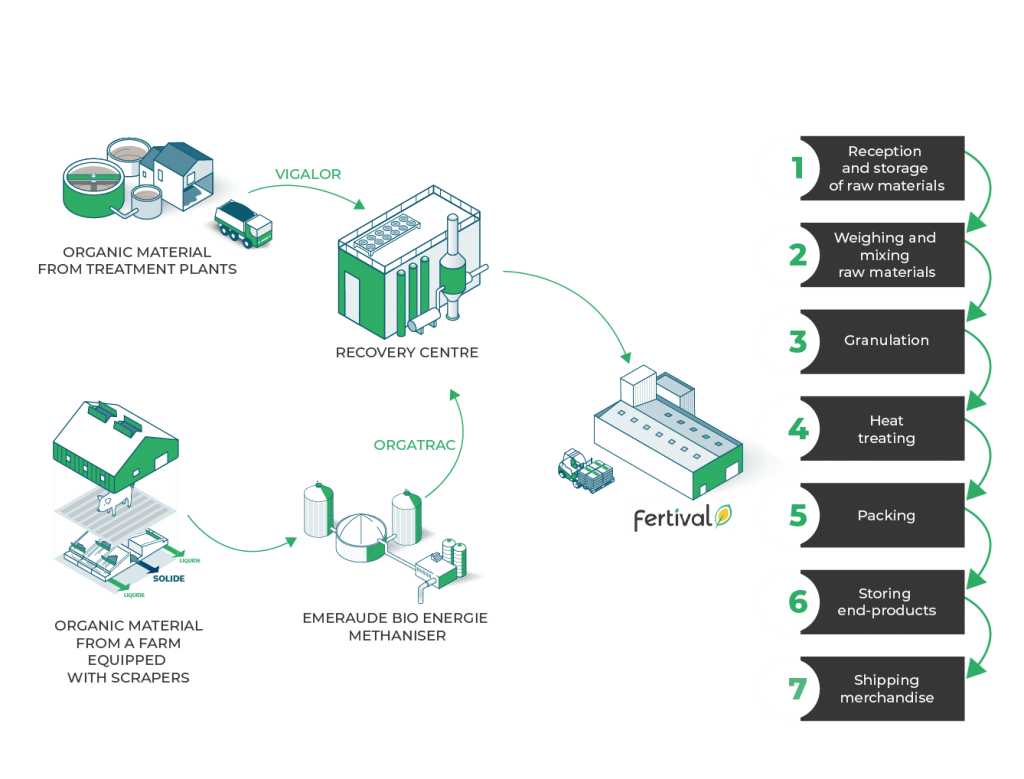

Our fertilizers are based on two main in-house raw materials: Vigalor and Orgatrac. Both are composed of organic matter from livestock, but their methods of extraction and transformation are different.

Vigalor is the raw material originating from the pig organic material collection and organic treatment stations, located adjacent to the livestock buildings. After a phase separation and a bacterial reaction, the farmer recovers the liquid part to irrigate his land and the solid component is transported to our Recovery Centre in Lamballe.

Orgatrac originates from the digestate created by Europe’s largest non-muck spreading methaniser (or bio-gas plant), created by Cooperl, in 2019. This tool is fed by the collected organic matter using a revolutionary robotic tool, which is installed in livestock buildings, entitled TRAC. This modern system has many environmental, livestock and health advantages. TRAC is a V-shaped scraper technology that ensures separation of the liquid and solids components of the waste. The liquid part is used directly on agricultural land. The solid component represents 90% of the Phosphorus and 55% of the Nitrogen discharged by the pigs, and is transported into Cooperl’s “Emeraude Bio-énergie” methaniser. Methanisation is an organic activity which enables organic matter to degrade, to produce bio-gas, which is then supplied to the GRDF network for consumption in Lamballe. The model’s special feature is that the digestate is recovered in its entirety, dried, standardised and not used for spreading, and our Orgatrac is obtained.

These two raw materials are dried and sanitised using renewable energy produced at the Recovery Centre. This drying stage also makes it possible to minimise the volume of transported material and thus to limit transport to the formulation site located in Quintenic, a few kilometres from Lamballe.

Nitrogen cycle

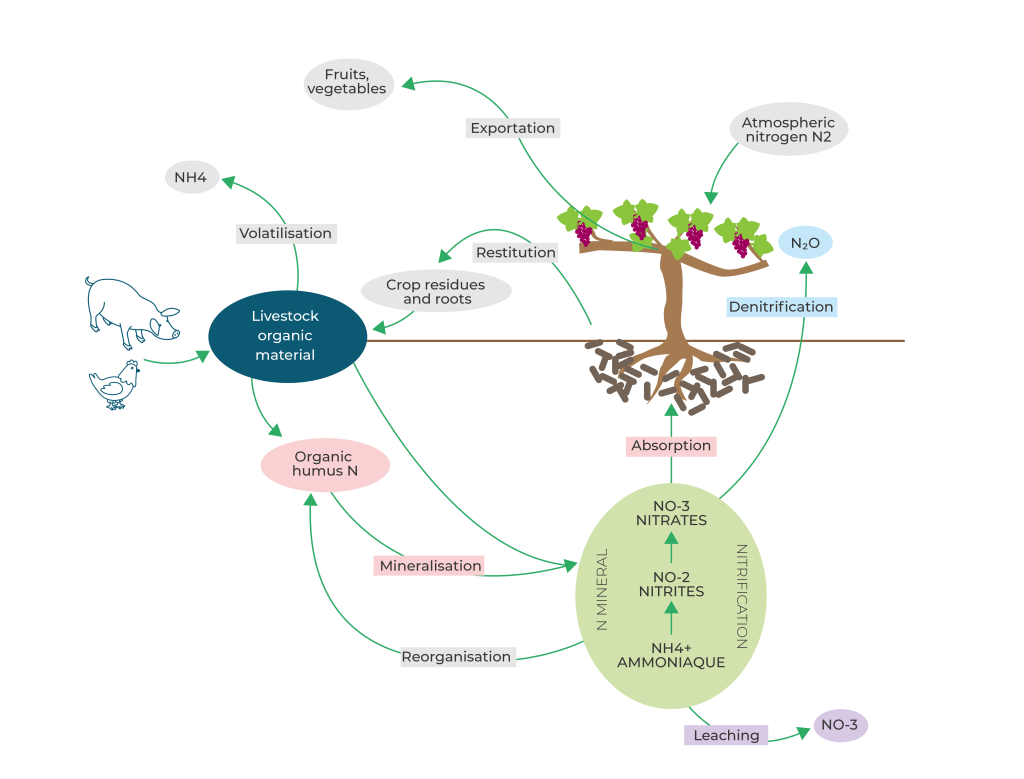

The nitrogen cycle is a bio-geochemical cycle in which the nitrogen in organic fertilizers undergoes processes in the soil in order to be absorbed by the plant:

- The process of mineralisation allows the transformation of humus into mineral material thanks to micro-organisms.

- Nitrification is a key step where soil bacteria convert ammonia into nitrite NO2- and then nitrite into nitrate NO3-, a form of nitrogen that can be absorbed by plants.

- Denitrification takes place when micro-organisms lack oxygen. Soil bacteria convert nitrate into nitrogen gas (N2) and release it into the atmosphere.

- The process of leaching refers to the loss of water-soluble nutrients dissolved and carried away by runoff water.

External raw materials

In order to optimise the granulation process and to offer you products adapted to the specific needs of your crops, we add organic or mineral materials from outside Cooperl to our formulas. It can be grape pulp, dry poultry waste, green compost or trace elements. First and foremost, we choose the quality and proximity of these materials in order to offer you a product in perfect fit with the nutritional needs you are looking for.