Cooperl our cooperative

Cooperl, agricultural and agri-food cooperative in western france

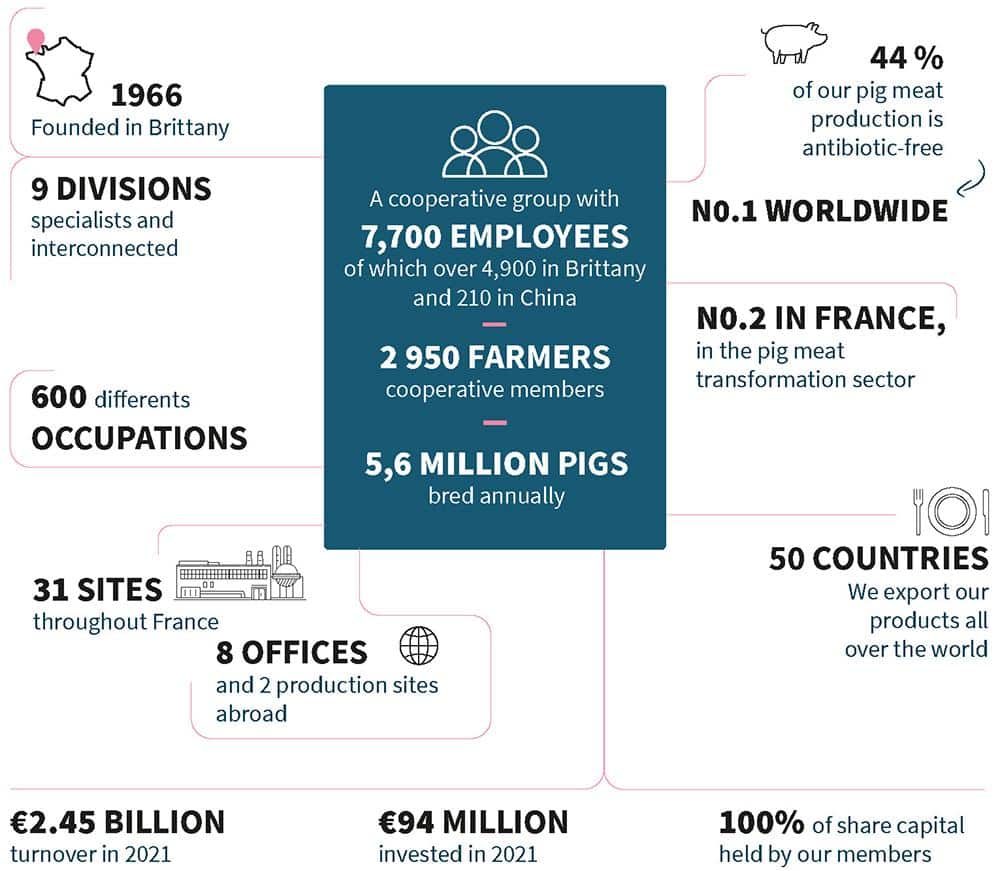

Established in 1966 by an association of 24 breeders from Lamballe in Brittany, France, Cooperl is now an agricultural and agri-food cooperative with 2950 member breeders, with 7700 employees and 31 industrial sites, which are mostly located in Western France.

Its strong innovative capabilities have led to numerous innovations with the creation of its own specifications such as the “Porc bien-être” (non-castrated pigs), “Porc élevé sans antibiotique” (pigs raised without antibiotics) or “Porc élevé sur paille” (pigs raised on straw with a GMO-free diet). The cooperative develops and designs modern, well-being livestock buildings, promotes “pesticide-free cultivation” to its members and makes nitrite-free, charcuterie products.

Cooperl combines respect for animals and people with ambition to move towards low-carbon agriculture.

Sector organisation

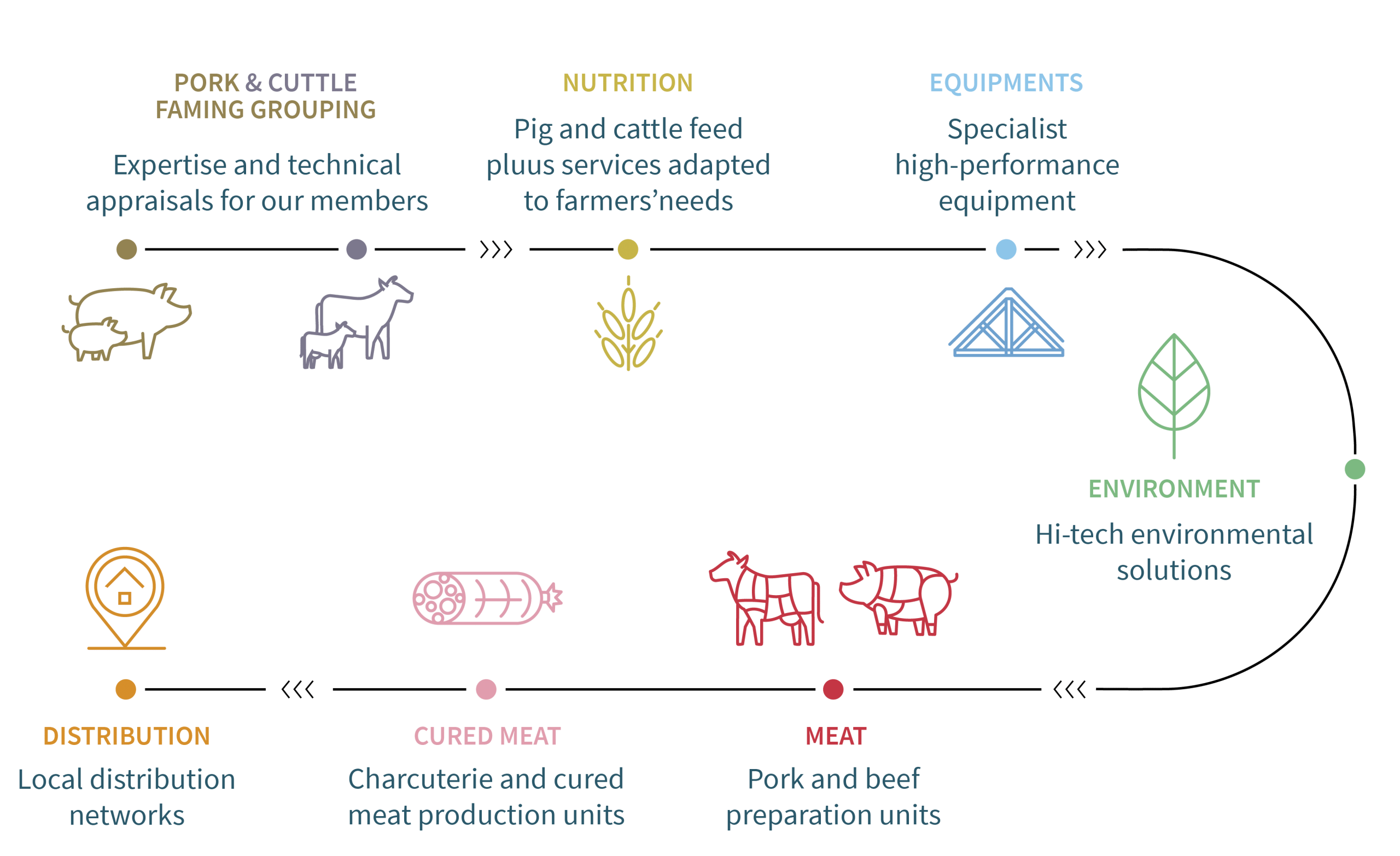

One of Cooperl’s major strengths comes from its sector organisation, from farm to fork.

Cooperl is organized around 9 mutually complementary branches of activity from upstream to downstream production. Each branch is specialized in a key stage of the breeding process: from designing livestock buildings to distributing end-products, and including animal feed or curing meat.

This networking makes it possible to bring together the know-how of hundreds of skills in order to master all the activities related to livestock farming. This strategy makes it possible for the cooperative to offer their customers innovative and responsible products, and to expand nationally and internationally.

Fertival is part of the “Cooperl Environnement” branch, at the heart of the circular economy model.

Spotlight on Cooperl Environnement

From the 1980s onwards, we became aware of the importance of placing the environment at the heart of our cooperative strategy.

Today, environmental issues have become adding value solutions. Each step creates a co-product, becoming a key resource for “Cooperl Environnement”s activities, divided into 4 distinct divisions.

4 distinct poles

The Ingredients division develops the notion of the non-edible 5th quarter of the pig (bones, blood, guts bristles) in the form of fats and proteins for the petfood market. These meal products are also used in our Fertival production facilities, providing nitrogen for our formulas.

The Bio-energy division includes the production of renewable energies, necessary for the proper functioning of the group’s facilities, such as steam energy and the hot water system.

In addition to producing bio gas, Europe’s largest non-spreading methaniser, developed by Cooperl, enables “Cooperl Environnement” to recycle several components: the digestate and an ammonium sulphate solution used in Fertivals natural fertilisers. In the future, Cooperl will also produce its own advanced bio-fuel capable of replacing diesel fuel , thanks to the fatty by-products from its food transformation plants.

The Natural Fertiliser division manages the entire livestock organic matter processing chain.

Collection, drying and sterilising are all carried out at the Recovery Centre, an important stage in the activity. Then by formulating and granulating, Fertival create natural fertilisers, dedicated to a variety of specific crops.

The Water division is responsible for processing, recycling and re-using the water in a closed circuit within the co-operative, thanks to a process of reverse osmosis, in order to preserve the networks of drinking water.

This unique circular ecology model allows the co-operative to ensure a supply of energy and raw materials, and reflects our commitment to sustainable development by limiting our environmental impact and reducing our carbon footprint.